Low Volume Molding Motor Housing Service Rapid Prototype

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB,FCA,CIF |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Air |

| Payment Type: | T/T |

| Incoterm: | FOB,FCA,CIF |

| Min. Order: | 1 Piece/Pieces |

| Transportation: | Ocean,Air |

Place Of Origin: China

| Selling Units | : | Piece/Pieces |

| Package Type | : | default: wooden case / carton, or according to customer's needs |

| Picture Example | : |

|

In addition to having a protective effect, The Motor Housing also acts as a component mounting rack. Some other special types of Motor Housing also have the function of heat dissipation or sound insulation. It can be manufactured by CNC engraving, Sand Casting, transparent acrylic(PMMA/PC) 3D Printing.

The production of castings needs to be carried out in a fully equipped casting workshop. In order to meet the strength requirements, the parts are cast under vacuum and then heat treated. One challenge to the casting technique is the inner shell sealing surface (Figure 2). An almost pore-free surface requires an extremely narrow process window. In addition to meeting these porosity requirements, due to the small dimensional tolerances, special attention must be paid to the handling of the product after machining.

Casting process of integrated motor shell

In addition to the two-piece design of the motor Housing described above and established in mass production, different design schemes have also emerged for future Electric Motors. The latest generation of electric drive units increase this clear trend of integration, such as electronic systems, electric motors and shift gears combined in an integrated housing, allowing the die-casting process method to meet process requirements. Therefore, the complex product design and cooling structure made low pressure die casting and CPS core casting the process solutions that made the shortlist.

Established in 2010, Wuxi SHINDEN Modern Intelligent Technology Co.Ltd aims to become a first-class rapid manufacturing enterprise in China.

We are committed to helping companies' R&D and innovation by providing product display solutions and test prototype solutions.

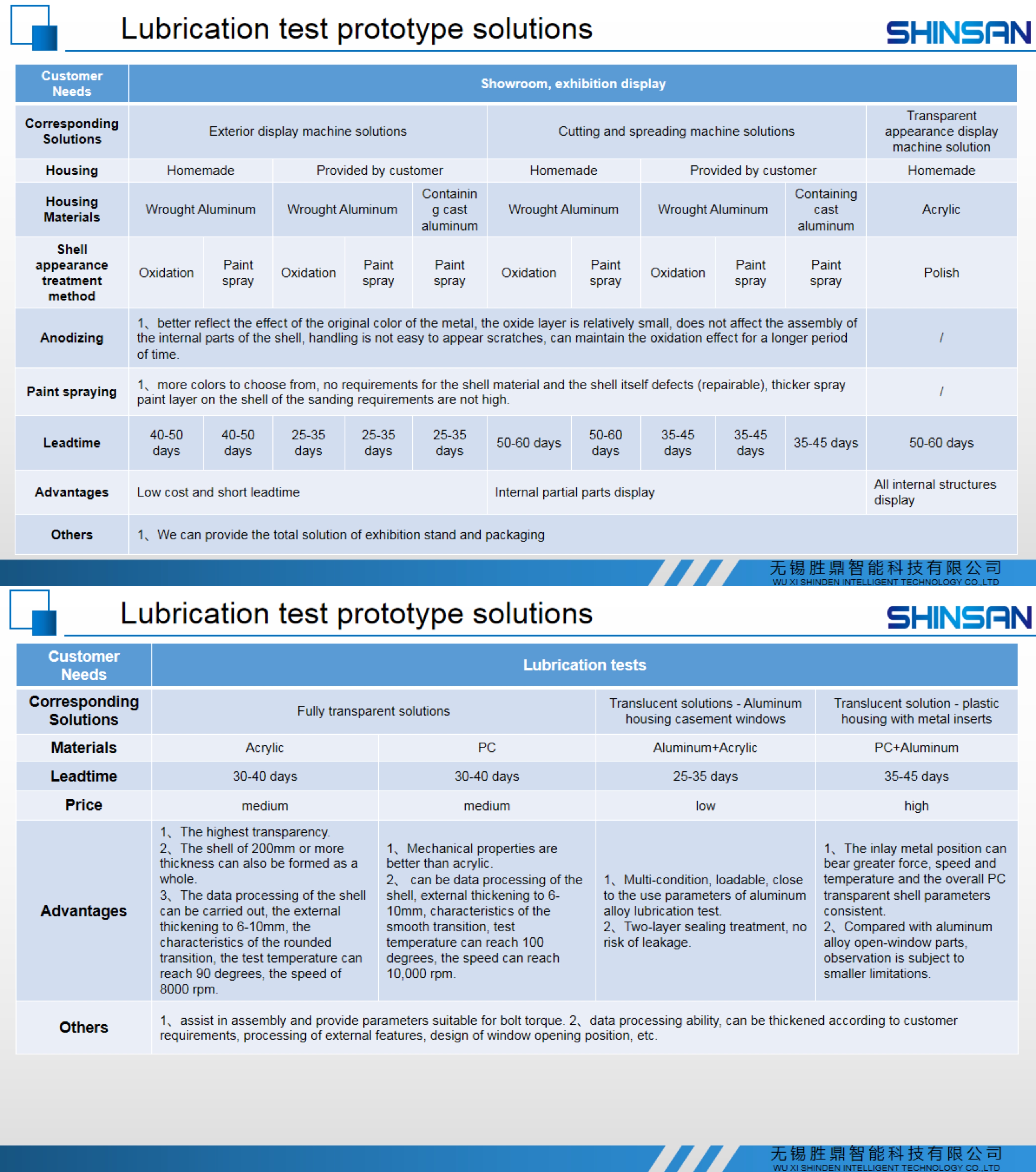

Product display package solutions include delicate process display machine solutions, cutaway display machine solutions and transparent appearance display machine solutions, from processing, assembly to simulation of dynamic operation. The design and manufacture of the display stand is easy to assemble and disassemble, convenient for packaging and transportation, multiple solutions to choose from and professional customization to meet the multi-functional needs of different customers.

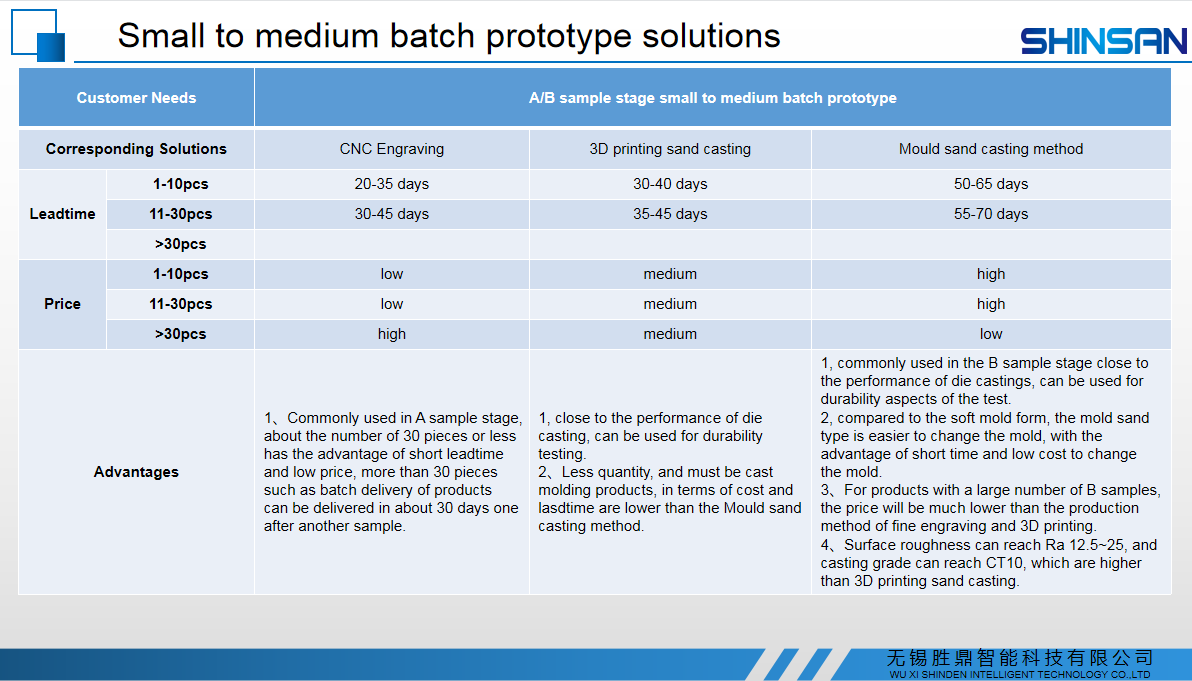

Small batch prototype solutions-engraving, short-cycle rapid prototype, suitable for new product development A sample, B sample stage. Small and medium batch prototype solutions - Casting, close to the characteristics of mass production die casting, suitable for new product development B and C stage and mass production up to 20,000 units/year. Test prototype solutions also include lubrication test, divided into transparent and translucent solutions, we have many years of rich experience in design and production, and we can customize solutions according to customer needs. We promise to provide professional and refined services to make our customers' products presented in the best way and help our customers’ R&D in the shortest time.

In the automotive field, we mainly serve the whole vehicle enterprises and core parts companies, with the service coverage of whole vehicle enterprises exceeding 95% and total service projects exceeding 10,000. We are also providing prototype and rapid medium and small batch manufacturing services for construction machinery, medical equipment, aviation and other industries. While deeply cultivating the domestic market, we are also carefully exploring foreign markets, mainly serving customers such as BorgWarner, Volvo, Bunch, Atlas, etc., mainly in Europe, North America, Oceania and other places.

Dimension: Based on clients' design drawing

Design: Based on clients' design drawing

Feature: Based on clients' design drawing and requirements

Surface treatment: as your requirements

Material: steel / aluminum - Any other material and dimension depends on customers' demand.

Usage: Machinery /Automobile

Processing Equipment: 5-axis machining center(800S U) / 3-Axis Machining Center(1270) / 3-Axis Machining Center(960) / 3-Axis Machining Center(850)

Checkout Equipment: CMM(coordinate measuring machine) / 3D scanner / X-ray fault detector / tool preseting measuring instrument / Roughness profiler / Cleanliness detector / Water and air double check air tightness detector

We are ISO 9001 / IATF 16949 / ISO 14001 / OHSAS18001 certified firm.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.